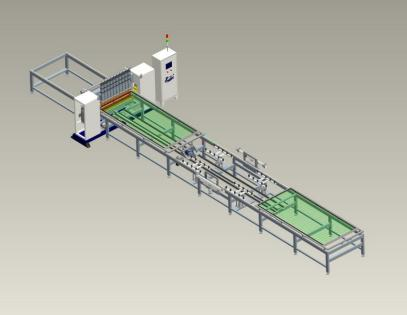

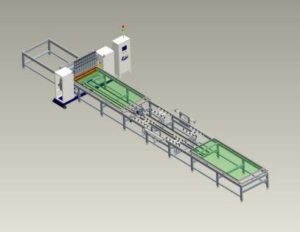

Ten Heads Automatic Wire Mesh Welding Machine

MODEL:WL-SQ-150Kx2

This gantry type spot welding machine adopts 10 welding heads and automatic feeding system. The operator only needs to put the material onto the feeder and press the start button, then the machine will conduct welding automatically. It is designed with double layer feeding system. The welding position could be set at random. The feeder will move front and back for welding. It is suitable for batch production of wire mesh.

The effective welding width is 1300mm while the effective welding length is 1300mm.

Design Concept

The Welding spots are good in looking, firm, and stable and reliable. Well consistency of

welding spots. Wide application. The machine, electricity and other mechanism could be reasonably assembled. It could be used to weld other similar products after relevant modification of microcomputer data program. One machine could serve several purposes.

Design Working Life:8-10 years.

Machine Composition:

Main Body:Adopt the reinforced special design steel structure body. According to the drawing, it is designed with 10 groups of welding heads. It adopts reasonable stress center of gravity to ensure the stable intensity of the main body when conducting fast speed welding. At the meantime, it could provide stress supporting point and working platform for other actions.

Power Source System: Adopt 2 sets of 150KVA special resistance welding transformer as the welding power source. Continuous duty cycle rate is 25%.The executive standard is GB/15578-2008; the magnetic permeability of forced temperature control cooling water silicon steel sheet is larger than 12000GS; special cooling water subloop; It can ensure the output welding current of the whole machine is constant and powerful in order to obtain high quality, high efficiency, stable welding spots.

Welding Method: It is designed with two-sided multipoint welding method. Equipped with six welding electrodes. The upper electrode could move. The lower electrode is designed as a large flat table to ensure large current on welding work piece. Then the stability of welding spots could be guaranteed.

Welding Control System: Adopt the self-developed intelligent microcomputer quick response touch controller, all-digital control, simple and clear operational interface. Automatic testing and compensation which could guarantee the situation that the machine will be at work only when the current value is in the preset data so as to ensure the stability of welding effect and effective prevention of undesirable phenomena like loose welding and cold joint. The features of quick response and high precision of control may help you obtain high quality of welding spots.

Pressurized Mechanism: Adopt single-layer cylinder as the pressurized source which is control by good quality of imported electromagnetic valve and coordinated with precision-machined linear slide to pressure the electrode tip. The pressure of each welding head could be adjusted independently to ensure the stability of welding machine. Adopt the working manner that the bottom bears the stress from the top to guarantee the good contact, unimpeded, constant resistance value of secondary circuit and stable transmission of output current of welding transformer. Guarantee to obtain high efficient and good quality of welding spots.

Main Engine Control System: Adopt the touch screen as the human-machine interface, English input. The PLC, as the control hub as the whole machine, is in charge of reading, transmitting and controlling all kinds of signal processing and coordinating with various external instructing transmission signal mechanism in order to ensure the validity of all orders of execution of the machine. The self-detection of all automatic testing stations effectively eradicates the occurrence of malfunction and other accidents. When the pressure, current, air pressure, hydraulic pressure, temperature or other testing signals are in abnormal situation, the machine will give an alarm to prevent any insecure accidents.

Automatic Feeding System: Be composed of the coding servo motor, precision-finished slide and automatic detecting system. The adjustment is of quick response, high control precision and powerful driving force. This feeding structure is equipped with one-way double-layer feeder and it will conduct automatic cycle working.

The coding servo motor is made in Taiwan whose advantage is precise locating, convenient adjustment of pitch and timing belt pulley transmission.

10 Heads Automatic Wire Mesh Welding

Machine WL-SQ-150Kx2

Adopt 2 sets of 150KVA AC Welding Power

Adopt Automatic Double-jig Feeding System

Effective welding range : 1300x1300mm

Automatic Ejection Device

with one set of 3Ph Water Chiller with

environmental friendly refrigerant R407C

with one set of free jig

Reviews

There are no reviews yet.