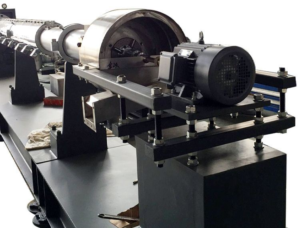

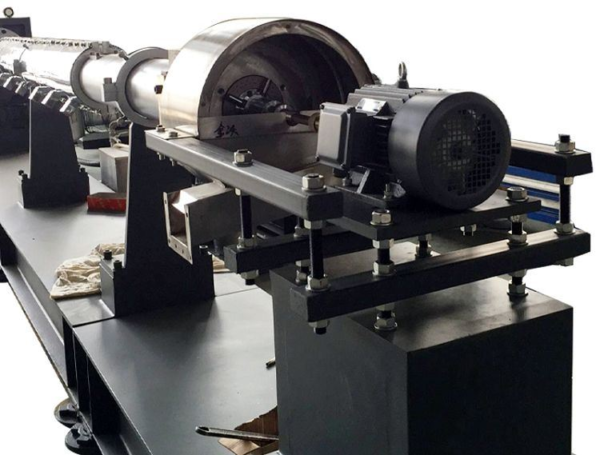

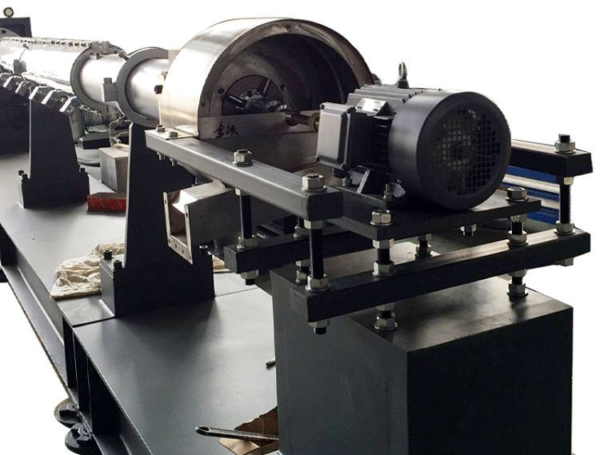

PP PE Film Recycling Granules Making Extruder Machine

SJ150-120 two stage single screw extruder with water ring pelletizing system for waste PP/PE plastic film recycling.

New screw design with many improvements,emphasis on energy saving and high yield.

Using hard tooth face gear box to improve equipment performance.

Exhaust type design is available to meet the recycled material processing.

Selected for dyeing granulation,wood and plastic extrusion,pipe,sheet,profiles extrusion,etc.

1.The gearbox:

New-style project of parallel three-axises driving makes the convey axis, convey chain, decelerate and the torque assignment get together, which keep it compact, and the key bearings are imported.

The select material of drive components is dainty, including super intension alloy cementiteing steel, cementiting and quenching, gear grinding technics, strengthening of tooth face. So they can ensure high torque, high precision and low noise.

Soakage and coerce lubrication integrate smoothly. When the hydraulic circuit is over pressed, it alarms.

2.The feeding system

Metering feeders are equipped with single screw, twin screw, hollow screw, forced-feeding, side feeding, liquid-adding system,etc.

3.Screw

The screw elements and then kneading blocks are designed accurately, by precise processed, agile combination, with interchangeability, which can fulfill efficient self-cleaning, transmission, compounding, pressure-forming.

The screw material is made of high tool steel 38CrMoALA or W6Mo5Cr4V2 by special heat-treatment.

4.The barrel

Euro style rectangle barrel, reflux refrigeration is optimized and disposed, which makes temperature difference in C areas smaller.

According to the material and special techinics demands, the material of cylinder can use high quality nitrided steel, corrosion proof or anti-friction with corresponding process.

5.The heater

Innovated design of heater tightened style insures high efficiency of heat transfer and high longervity of heater.

6.Pelletizing

Variou modes of pelletizing, such as water-cooling strand, air-cooling pelletizing, water-ring pelletizing, under water pelleting, etc.

Technical parameters

Type |

Dia(mm) |

L/D |

Motor(Kw) |

OutputKg/hr) |

SJ-20 |

20 |

28-33 |

2.2-4 |

5-10 |

SJ-30 |

30 |

28-33 |

5.5-7.5 |

10-30 |

SJ-45 |

45 |

28-33 |

11-22 |

30-70 |

SJ-65 |

65 |

28-33 |

37-55 |

50-150 |

SJ-90 |

90 |

28-33 |

75-90 |

120-250 |

SJ-120 |

120 |

28-33 |

132 |

250-450 |

SJ-150 |

150 |

28-33 |

220 |

450-700 |

SJ-180 |

180 |

28-33 |

315 |

600-700 |

SJ-200 |

200 |

28-33 |

400 |

1000-1500 |

44SJ-220 |

220 |

28-33 |

550 |

1200-2000 |

Reviews

There are no reviews yet.